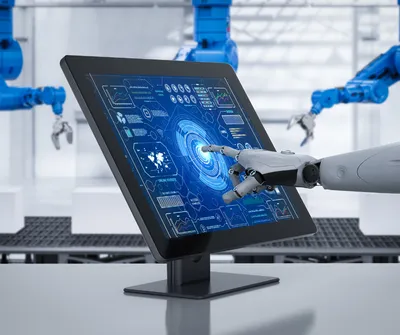

Kestria Industrial Production Global Practice Group has invited five esteemed experts from various industries around the world to discuss the latest advancements in artificial intelligence and robotics and their impact on transforming production lines and automation strategies.

Key takeaways:

Technological Efficiency: AI, robotics, and IoT are revolutionizing production by enhancing operational efficiency and sustainability. These technologies automate processes, reduce manual labor, increase precision, and optimize resource use, leading to higher quality and less waste.

Customized Production: AI allows for highly personalized manufacturing, adjusting production in real-time to meet specific consumer demands. This flexibility is enabled by AI-driven analytics and machine learning, facilitating faster and more accurate production from design to delivery.

Skills and Leadership: Effective integration of AI in manufacturing requires a skilled workforce and adaptable leadership. Upskilling, continuous learning, and strong leadership are essential to navigate the transition, fostering a culture that embraces technological advancements and innovation.

Current integrations and future plans

For Katja Gaiser from Switzerland, Vice President Global Operations & Supply Chain at Komax Group, the focus is on major virtual integration and ongoing digitalization. Foundational structures are being laid to integrate AI and robotics into processes. This includes leading a team to analyze relevant global technology trends to develop a strategic roadmap. Two years into this journey, the focus is on building a robust foundation to support a globally interconnected supply chain, primed for future automation enhancements. As the company transitions from a traditional, locally driven setup, there is a significant need for upskilling, reskilling and hiring to enhance competencies.

Jochen Mohn from Germany, General Manager at Hexagon, manages advanced measuring devices and scanning technologies for industries like automotive and construction. The company also offers CAD, CAM and simulation software to enhance productivity with real-world data. Based in Wetzlar, home to the world's most accurate measuring machine, Hexagon is building a smart, sustainable factory that will showcase full automation and AI integration. This includes creating a digital twin of the factory and using AI to streamline processes and remotely support technicians, reducing the need for travel. The ultimate goal is to integrate all these innovations into one exemplary factory.

Erich Weitgasser from Austria, Global Technical Director at IBS Paper Performance Group, represents a company that supplies specialized components and systems to the pulp and paper industry worldwide, with 24 locations globally. AI and robotics play pivotal roles, especially in enhancing quality control and safety in paper machine production, reducing manual tasks and increasing automation through algorithms. A significant challenge is managing and integrating data from various global systems to ensure accuracy and compatibility, crucial for optimizing AI applications due to the data's scale and diversity.